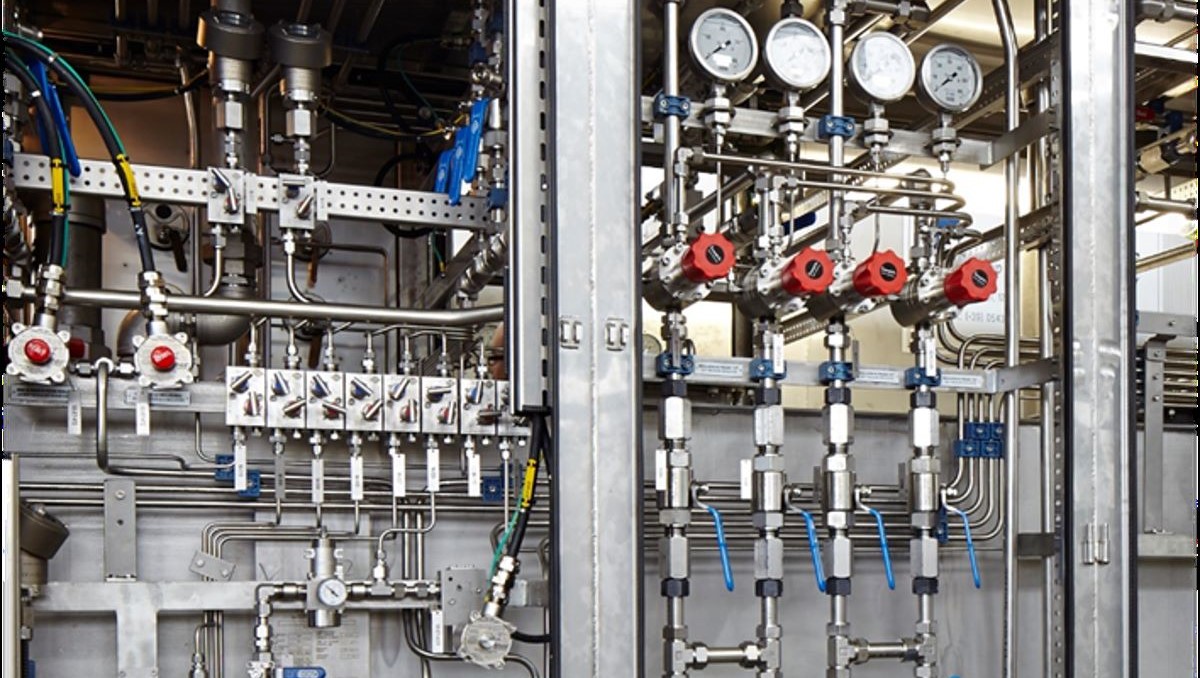

The CompEx SBT inspection qualification has been developed for SBT technicians working on industrial installations containing Small-Bore Tubing assemblies.

Attendees

This qualification is suitable for practicing SBT installation, inspection and maintenance technicians.

Entry requirements:

Evidence of training or assessment in the installation of SBT assemblies

E.g. ECITB SBT 01, 02

ECITB TSBT 01, 02 or equivalent

Duration

3 days

Delivery

The 3-day course includes:

- Stage 1 (0.5 days) – face to face or E-learning

- Stage 2 (2 days) – face to face with a licenced training provider

This qualification has been developed in consultation with industry and is aligned with the competency requirements for persons maintaining and inspecting SBT assemblies defined by the current edition of the Energy Institute guidelines for the design, installation and management of small-bore tubing assemblies.

The course includes a recap of SBT installation techniques (Stage 1) and goes on to cover in stage 2 the relevant legislation, hazards and risks associated with SBT assemblies, components used in SBT assemblies, pre job planning and preparation for visual inspection of SBT assemblies, visual inspection of SBT assemblies and reporting requirements.

Successful candidates will be able to meet the requirements of the knowledge and skills highlighted in the Energy Institute Guidance.

Key learning objectives

Learners that successfully complete the CompEx SBT Inspection qualification will be able to:

Stage 1

K1.1 – Identify twin ferrule, and cone and thread fittings.

K1.2 – Identify tools and equipment used to fabricate and install SBT assemblies.

K1.3 – Identify tubing and pressure ratings.

K1.4 – Identify SBT support systems.

K1.5 – Identify SBT components from engineering drawings.

K2.1 – Explain hazards associated with visual inspection of SBT assemblies.

K2.2 – Explain mitigating control measures associated with visual inspection of SBT assemblies.

K3.1 – Identify relevant regulations, ACOPs and industry practice.

K3.2 – Explain the importance of following relevant regulations, ACOPs and industry practice.

Stage 2

K1.1 – Identify from asset registers and drawings the size, type, and functional locations of SBT assemblies.

K1.2 – Identify from asset registers and drawings the inspection priorities of SBT assemblies.

K1.3 – Recognise SBT inspection criteria norms for tubing, fittings, supports and instrumentation, including corrosion mechanisms.

S1.1 – Determine the location of the SBT assemblies to be inspected.

S1.2 – Complete a line walk, point of work risk assessment and a toolbox talk.

S1.3 – Complete the preparation of tools, equipment and materials for visual inspection of SBT assemblies.

S2.1 – Complete the visual inspection of tubing, fittings, supports and instrumentation.

S3.1 – Complete SBT inspection reports, update SBT asset registers and tag SBT assemblies

Note:

K = Knowledge

S = Skills

Qualification details

Candidates who are successful in both the theory and practical assessments will receive a CompEx Certificate in Core Competence.

Assessment:

Assessment is undertaken using practical assessments and online knowledge examination.

Online exam

Learners must undertake a multiple-choice online examination that consists of 60 questions answered over 1.5 hours.

Practical Assessment

Candidates are required to undertake the following practical assessments:

- SBT inspection (live)

- SBT inspection (Dead)

Find a centre

Find your nearest licensed CompEx centre and get full contact details using our simple map facility.

Retain certification

Achieving CompEx core competency is essential for practitioners who work in potentially explosive environments, but competency must be maintained following certification.

Resource centre

The CompEx resource centre provides all the essential forms, documentation and downloads that you may need for CompEx training and registration